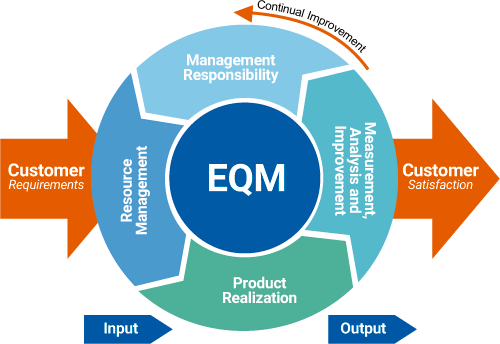

Discover the solution that optimizes your company’s quality management processes

Modernize your quality management system, reduce the work required to maintain compliance, improve agility and transparency and promote continuous improvement across your organization while increasing customer satisfaction.

Key benefits

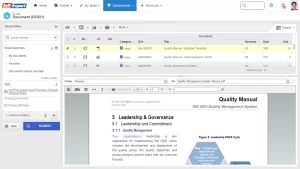

Traceability

Have full control over the process of creating, revising, approving, storing, and canceling documents in an easy and secure way, maintaining compliance, history, and traceability of information.

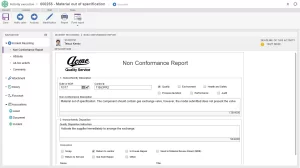

Centralization

Aggregate the registration and handling of nonconformities and incidents in one place, turning them into opportunities for improvement and reducing the likelihood of recurring quality deviations.

Optimization

Turn your audit forms and checklists into electronic tools and say goodbye to unnecessary paperwork.

Security

Identify, assess, and define control practices to proactively mitigate risks, ensuring the security of your processes.

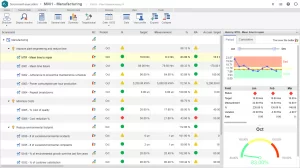

Clarity

Monitor quality indicators through personalized and interactive portals, so that you and your team have a clear view of your operations and support for decision making.

Compliance

Make it easier to adjust processes to meet national and international standards and accreditations such as ISO 9000, Good Manufacturing Practices, among others.

Become more agile and transparent, and drive continuous improvement across the organization

SoftExpert EQM is a complete solution for quality planning and control, management of documents, non-conformities and incidents, organizational changes, audits, risks, quality inspections, suppliers, employee skills and training, customer complaints, corrective and preventive actions, performance indicators and other essential processes for the effective management of your quality system.

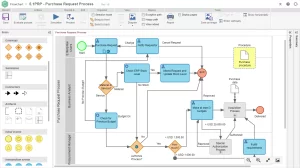

End-to-end management of quality processes

- Conduct internal and external audits electronically. Create checklists based on your certification processes and standards, manage the entire audit lifecycle, and track your results in real time.

- Streamline customer service management, enabling complaints to receive the necessary treatment with the agility and clarity they deserve.

- Automate your supplier qualification assessments based on pre-established criteria and measure their performance throughout the relationship lifecycle.

Continuous improvement of processes

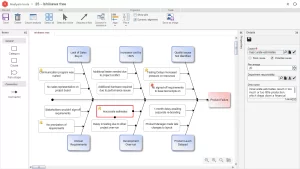

- Apply quality tools such as Ishikawa Diagram, 5 Whys, Pareto Chart, and process control charts to identify failures, threats and analyze the root cause of problems.

- Plan, control and record all training required and carried out by your employees and suppliers, ensuring execution and the assessment of effectiveness.

- Standardize your organizational change process and effectively manage approval, implementation, and verification steps, ensuring compliance with your internal and regulatory requirements.

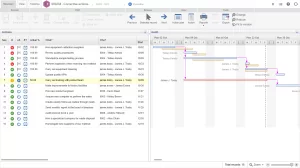

Action plans under control

- Use the 5W2H method to register corrective and preventive actions and view the activity schedule with Gantt charts.

- From registration to completion, stakeholders are automatically notified at every step that requires their attention, ensuring deadlines are never missed.

- Attach evidence and control the entire action plan from creation to verification of effectiveness and closure.

Optimization of activities

- Monitor the execution of activities in real time using personalized portals and eliminate failures, events that result in rework and activities and decisions that fail to comply with quality guidelines.

- Turn your meetings into real results, optimizing the time of everyone involved, automating management, and including schedules, agendas, minutes and activities for responsible parties.

- Control calibration and maintenance plans on a single platform and ensure traceability of all instruments and equipment in your company.